A week ago, I was able to buy a cool old drill press off Craigslist. I know, I know. I already have an old drill press, so what would I do with another old drill press? Well, I don't really know. I thought I could justify it by saying, "one for wood and one for metal", but I don't think I need to justify it. It's just cool.

This was a 1940s Walker Turner drill press that has been handed down through a family. Purchased new by the grandfather, then passed down to his son, and then to the grandson. I think it's pretty cool this old machine stayed in one family so long, so now I feel part of it!

It hasn't been turned on or used for 20 years, so said the current owner. It had alot of surface rust and dust from 2 decades of storage.

The 80 year old motor is super heavy duty. Even though it is only 1/3 HP, it weighs like 20 pounds. It does start and spins, but the start cap is a bit weak, so I'll replace it. The bearings sound pretty smooth.

Perhaps the coolest feature is that extra hand-crank on the right hand side of the machine. It lifts the entire head. Yes - rather than raising or lowering the table, this has a gear mechanism that raises/lowers the entire head/motor assembly. Wow!

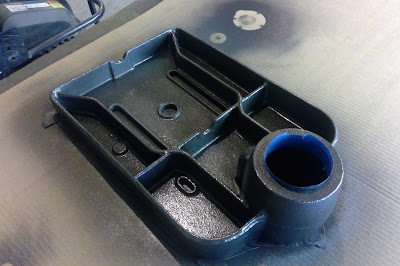

Another unique feature is this X/Y stage beneath the working table of the machine. It's frozen solid, but it's very similar in construction to a lathe cross-feed of which I'm familiar with. I'll get this working, too.

Wires on 80 year old machines are always in bad shape.

Check out this dry rot!

However, I was surprised to see color on the wiring within the junction box. Usually those wires all fade to dull black and you can't tell what is yellow or green or red or black.

I blew off about 5 pounds of dust, and removed the on/off switch in order to see the original paint color below. I plan to tear this down and give it the full restoration, so I wanted to see this original color.

I usually try to always stick close to the OEM color, but I don't think I will in this case. Olive green drab just doesn't strike me as a very snazzy color. So I'm going off the rails and doing something I haven't done before: I'm changing up the color scheme.

I cleaned up a piece and tested out a color to see how well I like it.

And I like it!

This is Krylon Hammered Dark Bronze spray paint. It has a hint of a sparkle and I think it looks really good. It will compliment the future-polished pieces nicely. I'm going to go with this.

Note: I've used Rustoleum for years, and after years of a love/hate relationship with that brand, I'm ending that relationship on "hate". I believe 50% of my spray cans get clogged up in the first few seconds of use. I'm no idiot - I know how to paint and how to prep. I feel Rustoleum has lost its quality. I even called their customer service hotline to complain, and was given the standard corporate blow-off reply, so I'm switching to Krylon. So far, so good. I'm quite impressed!