Just a sanity check to see if this ol' blog still works.

Thursday, March 9, 2023

Friday, August 27, 2021

Chimney Repairs

Once we returned from the Boundary Waters, we had contractors arrive to repair our failing chimneys. We have two chimneys, and they were both broken down so much that they were irreparable. Cracks in mortar and brick allowed water to get into the house (into the breezeway). So the only option was to tear down and rebuild.

Cracks in the crown allowed water to seep into the underlying cracked mortar and brickwork.

Thursday, August 26, 2021

Drill Press Challenge

Now that I own a whopping 3 drill presses, I thought I would see how well they perform in accuracy. This may be a hotly debated topic, but I think of "runout" when I think of accuracy. That is, how well centered does a cutting tool travel in relation to the center axis of the quill? I have a dial indicator, so I can find out.

First up is my most recent acquisition - the Walker Turner drill press with a best estimate date of manufacture in the 1940s:

Find the low spot on a straight and solid shaft, zero the indicator, and then manually rotate the belt to rotate the quill to find the high side. In this case, I'm showing about 0.0045 (four and a half "thou" as in thousandths of an inch). Not bad.

Next up is my Atlas drill press given to me by my Uncle in Peoria. I absolutely love this machine: It's quiet, and smooth, and it has never let me down. It also has the speed reduction intermediate pulley set for slowing down rotational speed. Thus, it is a good metal drilling tool. I believe this machine is 1950s vintage.

Results for the atlast: 0.0125 - about twelve and a half thou. This is about 3x worse than the Walker Turner machine. Hmmm.I thought it would be cool to put a pencil in the chuck, and rotate it to visualize this runout. It's easier to see this way.

I've read on some machining forums that the 3 jaw chucks in drill presses can wear after alot of use. I believe that is the case for the Atlas - things appear to have some wear. For this last drill press with nearly 3/16 of an inch of runout, I think the chuck itself is not centered in the quill. I don't use it, so I'm not going to bother repairing it. It's just a nice show piece.

Wednesday, August 25, 2021

Catching Up - BWCA Trip

Wow - 2 months went by in a flash, and I haven't posted a single update. That's just a sign of the busy times we're in. Lots going on.

A month ago, we were in the Boundary Waters on this day of the month. It was a good trip, despite some mechanical challenges getting there and back. Here's just a few pictures.

After 750 miles of travel, we made it to our entry point of "Homer Lake" on an overcast morning. We had 3 kids, 6 packs, and 2 canoes. That's all we were able to manage to take.

It was a great trip, and we got this trip in right before the National Forest Service shut down the entire BWCA due to wildfires. Yes, the entire 2100 square miles of Park Area had to be evacuated (and still is at the time of this writing). Crazy!

Thursday, June 24, 2021

Walker Turner Drill Press - Restoration Complete

I've been slowly putting the old Walker Turner drill press back together. It's fun to take it slow and do it right. I've got the time.

It turned out all very well, and every piece is functional.

I do not have the X/Y/theta stage restored at this time, but it's on my list to do. That will have to happen later this summer. For now, I've got some other projects bubbling to the top of the priority list.

Side Story: My lovely wife helped me move this drill press from one workbench to another so I could get some good pictures. Oh man, this is one heavy heavy piece of equipment. While we managed to move it with just the two of us, I had some flashes of panic as to if we were going to make it at about step #3 (out of 5 steps total). After taking pictures, I had Kid #1 and Lovely Wife help me move it back to its final home. That was the way to go. I shouldn't underestimate the strength of my daughter. Lesson learned.

Friday, June 18, 2021

Jumping Ahead - Walker Turner Restoration

It's been a busy week, but I've managed a little more progress on this old drill press. Temperatures and humidity have been very good for paint, so you have to make hay while the sun shines. I think that's how it goes.

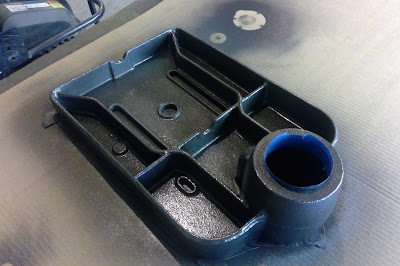

I took apart the mechanism that raises and lowers the head of the drill press. Even though there is 80 years of caked-on goo, it wasn't too difficult to loosen and remove the hardware.

I hope over the weekend I can start reassembling many of these pieces back together. It should be a fun puzzle.

Friday, June 11, 2021

Progress on the Drill Press Restoration

It's been a full and busy week at the house with a full schedule of work and kid activities picking up. But I was able to sneak away in the late evenings and do a little work on the old drill press.

I tore apart most of the pieces out of the head. The spindle mechanism and all the related parts came out pretty easily.

I have a three day weekend coming up, so I hope to get a little more done as time allows.